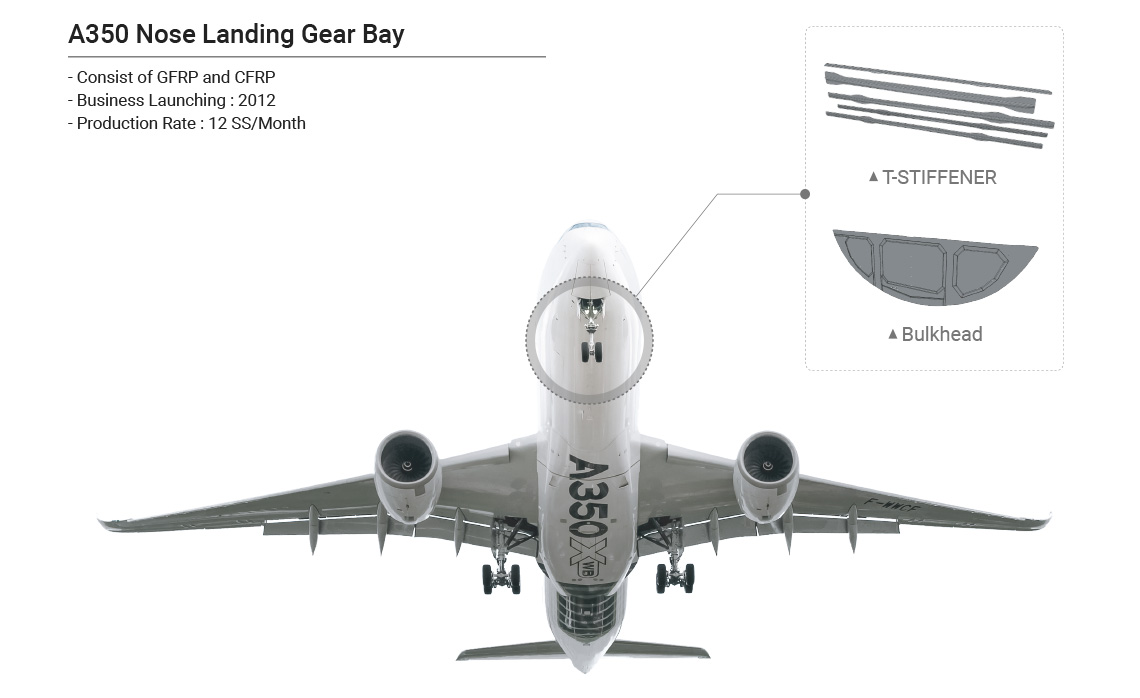

The Airbus A350 XWB is

A type of Airbus aircraft. The A350 XWB is the first of its type to be manufactured from carbon composite plastic, with most of its fuselage and wings.The A350 is designed to compete with Boeing 777 and Boeing 787 Dreamliner, while Airbus says the A350 XWB can save operating costs more than the Boeing 787 Dreamliner. Korea Composite Materials has technologies that can maintain excellent quality such as Airbus A350 Nose Landing Gear Bay and A350 WXB Business Class Back Shell manufacturing, and is continuously supplying them to Korea Aerospace Industries (KAI).

MANUFACTURING PART

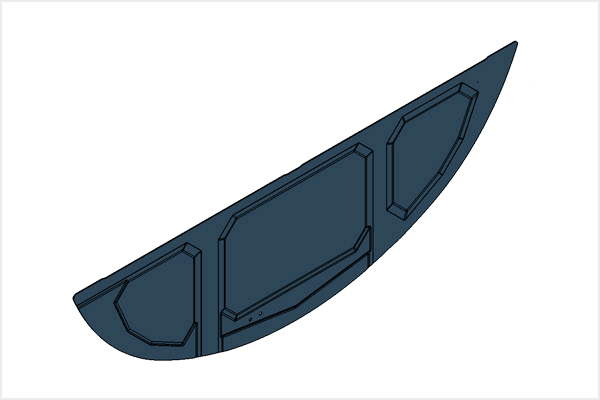

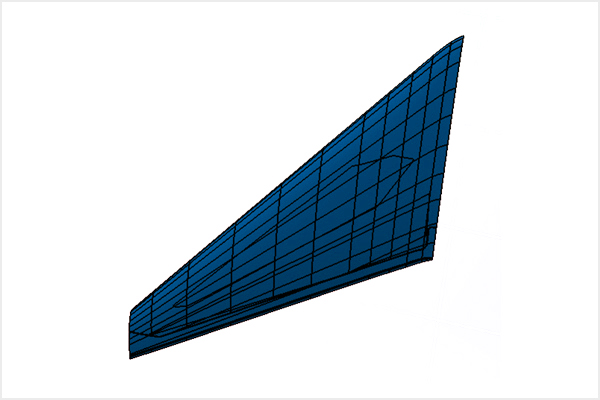

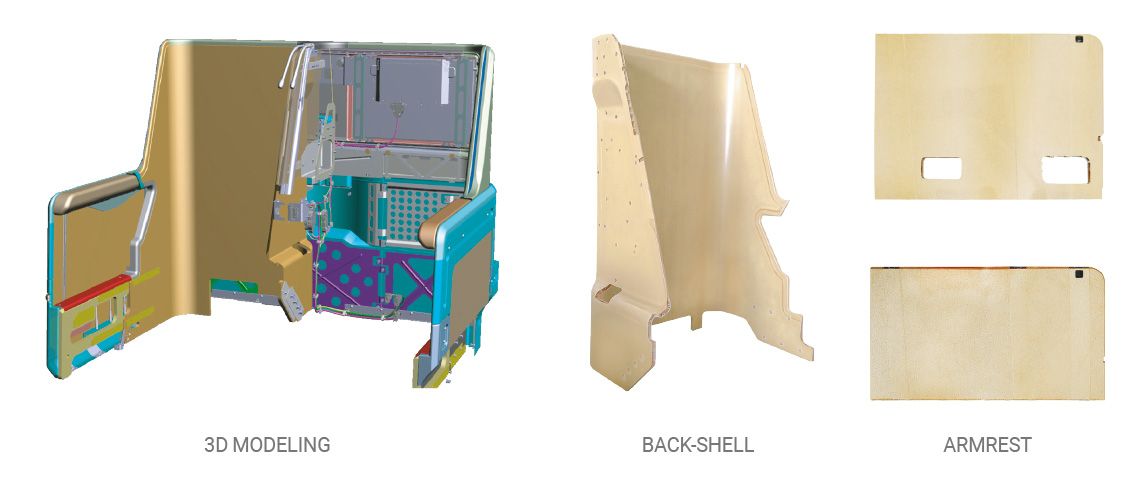

A350 WXB Business Class Back Shell

Consist of GFRP, CFRP and Honeycomb

Business Launching : 2012

Glass/Phenolic Prepreg is developed by Mother company(Hankuk Carbon)

| Test Mode | Test Method | Requirement | HPA7781-S Results (honeycomb sandwich) |

|---|---|---|---|

| Drum Peel Test (Warp direction) | ASTM D1781 | 50N/3in | Tool side: 60N/3in Bag side: 54N/3in |

| Flammability Test (60sec, vertical) | FAR 25.853 | Self-extinguishing time: 15 sec | 0 |

| Burn Length: 6 inch | 1in | ||

| Drip extinguishing time: 3 sec | No drip |

Product Detail

| Part Name | Material & Plies | Size(㎡) | Weight (㎏) | Thickness (㎜) | Remark |

|---|---|---|---|---|---|

| Bulkhead | CFRP : 40 + GFRP : 2 | 8.89 | 31.4 | 7.49 | |

| T-Stiffeners | CFRP :40 + GFRP : 3 | 0.59 | 2.62 | 7.49 |

Delivered more than 424 ship sets(10 Ship sets/month) since 2012

Indirectly export products to Airbus through KAI

Product Quantity

| Part Name | Quantity/ 1 set |

|---|---|

| Bulkhead | 1 |

| T-Stiffener | 5 |

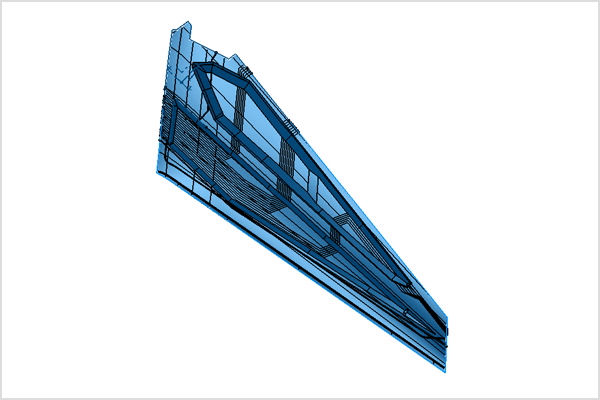

3D Modeling

It is a model developed by

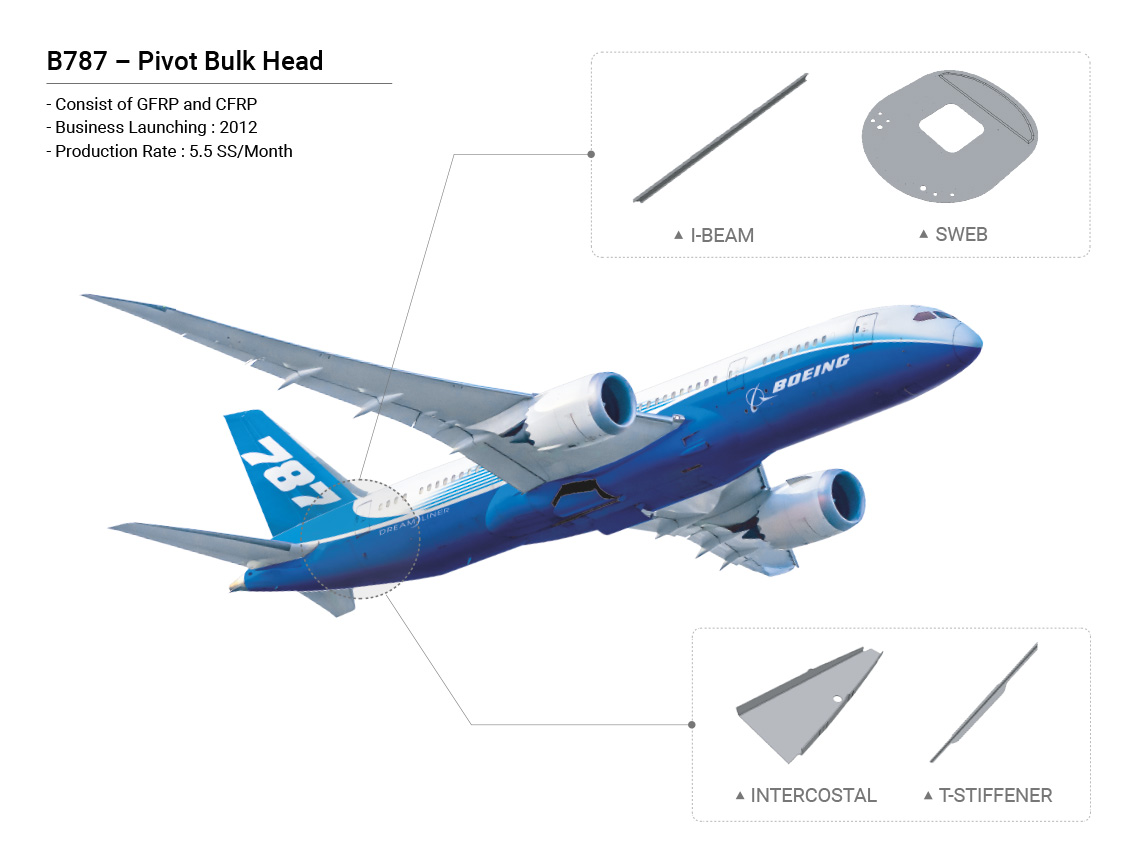

Boeing that replaces the existing mid-size Boeing 767 with medium-sized long-range photovoltaic twin-engine passenger jets, and is also part of Boeing's plan to replace the 777-200 series for the launch of the 777X.The 787 is an abbreviation for "Dreamliner" and Boeing itself uses the nickname "Dreamliner." The B787 and A350s are medium-sized, 440-seat aircraft, both of which are based on the maximum number of seats.Korea Composite Materials manufactures Boeing B787 Pivot Bulk Head, B787 Fixed Trailing Edge, P-8 Horizontal Stabilizer & Raked Wing Tip, etc.

MANUFACTURING PART

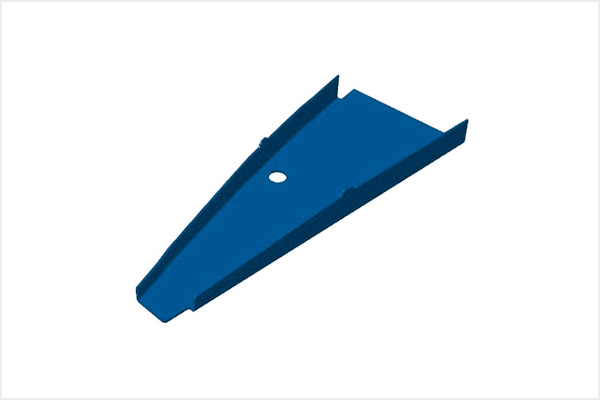

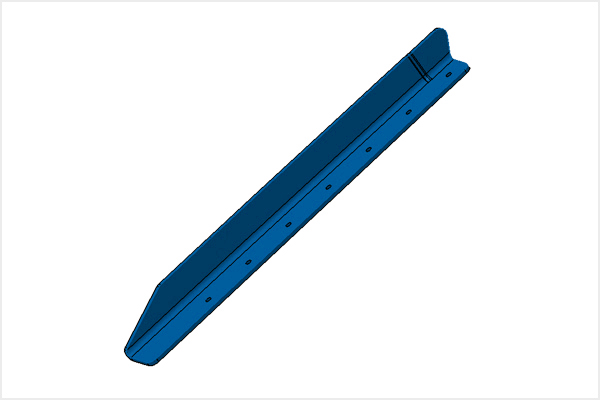

Product Detail

| Part Name | Material & Plies | Size(㎡) | Weight | Thickness | Remark |

|---|---|---|---|---|---|

| Web (Pannel) | CFRP : 38 + GFRP : 2 | 11.24 | 58.04 | 7.1 | |

| T-STIFFENER | CFRP : 22 + GFRP : 3 | 0.32 | 1.01 | 4.18 | |

| I-Beams | CFRP : 30 + GFRP : 4 | 0.84 | 2.61 | 4.68 | |

| Intercostals | CFRP : 28 + GFRP : 2 | 0.755 | 3.16 | 5.45 |

Delivered more than 300 ship sets(5.5 Ship sets/month) since 2012

Indirectly export products to Boeing through KAI

Product Quantity

| Part Name | Quantity(1set) |

|---|---|

| WEB | 1 |

| T-STIFFENER | 18 |

| I-Beam | 4 |

| Intercostal | 8 |

3D Modeling

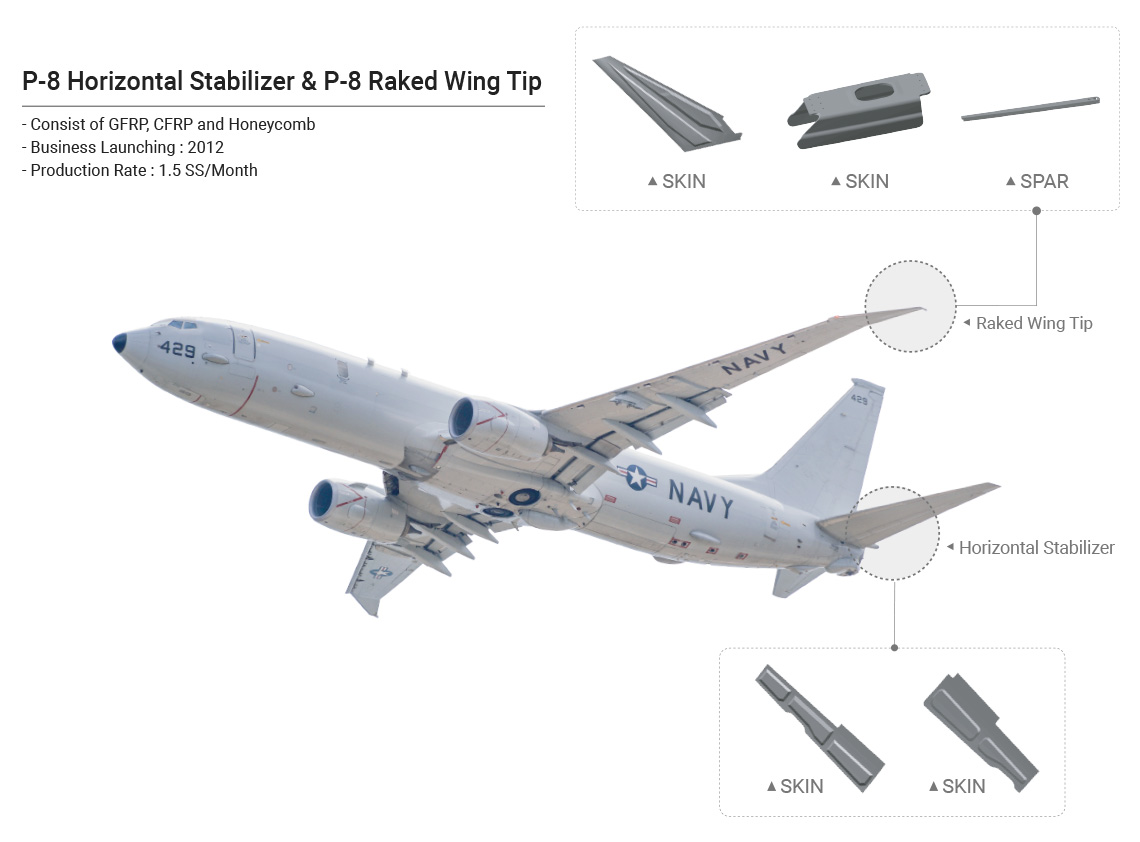

Korea Composites Inc is

In the early stage of the project, the company began bonding various composite materials components for aircraft from the work site of the Korea Aerospace Industries Corporation, and acquired various experiences such as KUH Floor, Skin and Cockpit to secure technical skills in the composite materials field of aviation.

MANUFACTURING PART

Military Project

T-50 (KAI)- Since 2015

- Wing/Empennage Components

KUH (KAI)- Since 2012

- Cockpit

- Air Conditioning Ducts

- Floor

- Skin

A-10 (Boeing)- Since 2012

- Wing Skin Closure

- Aileron Strap/Seal

UAV (HANKUK FIBER GROUP)- Since 2015

- Wing/Empennage Components

GPS Guide Bomb (LIG NEX1)- Since 2015

- Flaperon

- Surface

- Faring

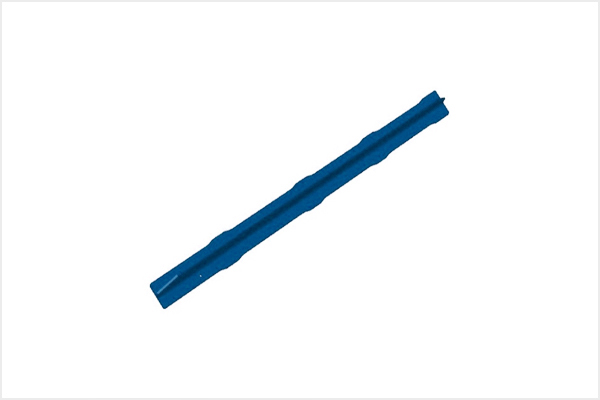

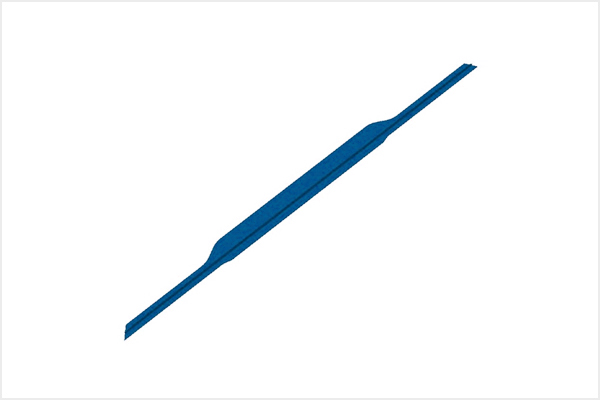

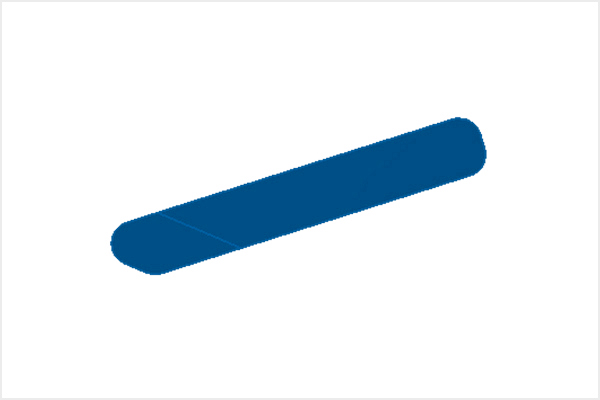

Product Detail

| Part | Material & Plies | Size(㎡) | Weight (㎏) | Thickness (㎜) | Remark |

|---|---|---|---|---|---|

| Spars | CFRP : 22 + GFRP : 2 | 0.43 | 2 | 5 | |

| Skins #1 | CFRP : 6 + GFRP : 8 | 1.1 | 3 | 2.7 | |

| Skins #2 | CFRP : 33 + GFRP : 2 | 3.0 | 29 | 7.5 |

Delivered more than 140 ship sets(1.5 Ship sets/month) since 2012

Indirectly export products to Airbus through KAI

Product Quantity

| Part Name | Quantity/ 1 set |

|---|---|

| Skin | 18 |

| Spar | 12 |

3D Modeling